Effective Germ Prevention In A Touchscreen-Friendly World

- BenQ

- 2020-10-23

How Proven Anti-Microbial Technology Can Improve Student Classroom Health

Medical Grade Touch Technology for Safer Collaboration

In interactive learning environments, such as hybrid classrooms, students use interactive boards, such as interactive flat panels (IFPs) to do group activities together and solve a problem side by side on the same display surface using just a finger. While these activities help students to learn and succeed, they can also rapidly and unknowingly spread dangerous pathogens through touch. As the use case for IFPs in the classrooms soar, educators now have to think about how to limit the spread of these germs.

Although this is a new problem for education, hospitals have been aware of the challenge of delivering quality care using the latest touch-enabled equipment for years. This has led to the development of medical-grade anti-microbial materials, such as nano-ionic silver. Many items found in a surgical theater have integrated anti-microbial protection such as surgical lighting, touch panels, and other devices that are handled frequently to avoid cross-contamination.

How It Works

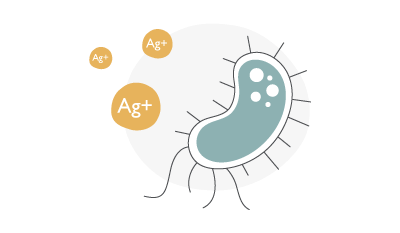

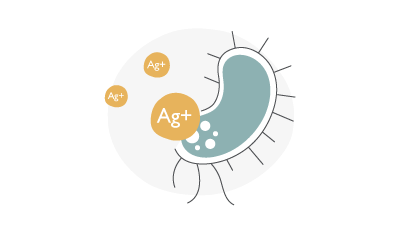

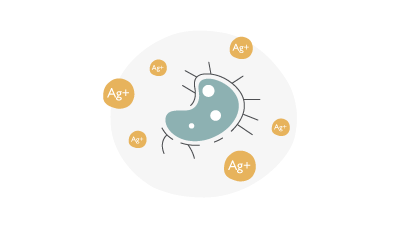

Silver nanoparticles (AgNPs) work by releasing silver ions (Ag+), which is absorbed by the pathogen. Ag+ inhibits cell division and replication of the pathogen. Within the U.S. the use of AgNPs is recognized as being effective and certified for use in hundreds of consumer and medical such as surgical masks, food containers, water filters, bandages, and biomedical devices.

Silver nanoparticles (AgNPs) release silver ions (Ag+).

Ag+ is absorbed by the pathogen.

Ag+ inhibits cell division and replication of the pathogen.

In 2017, BenQ recognized the opportunity to protect students using a silver ion nanotechnology protective coating on their new IFPs to reduce the spread of bacteria and viruses. There are dozens of scholarly papers from around the world that detail findings on how this technology is used against various types of pathogens.

How BenQ’s Proprietary Glass Technology Helps Keep Students Safe

To limit the growth of germs on an interactive touch screen, BenQ coats the glass with silver ion nanotechnology using a special manufacturing process. To make the silver-ion coating effective, the glass is coated with the nanoparticles and precisely mixed into a proprietary recipe that enables the panel then to be cured. These are applied to displays as large as 86 inches and requires expensive equipment and special handling to ensure they do not crack or break. Once the glass is cured, it’s incorporated into the interactive panel.