Why Dustproof is Vital in a Projector World

- BenQ

- 2021-08-23

Dust is a creeping venom as far as projectors in general and simulator projectors in particular are concerned. Almost unnoticeable at first, dust creeps in, accumulates inside, causes overheating, and poisons your optical engine, until definition gets blurry, and color and projector quality decay.

Dust can be a problem for simulator projectors, but BenQ has the solution: Dust Guard technology

To call a spade a spade: dust accumulation will affect image quality and color and wreck projection quality. It will also seriously harm projectors or even destroy them completely.

A laser optical engine is composed of many highly sophisticated optical components such as a laser diode, lens, phosphor wheel, color wheel, all of which are sensitive to dust-damage.

Projectors with prolonged exposure to dust will have particles accumulate inside them gradually - the so-called dust cake. This leads to color and brightness decay, heat accumulation, abrasion of the optical components and permanent, irreversible damage.

This is especially the case for the laser diode. Dust particles leave residue and accumulate heat which causes permanent damage and eventually destroys the component.

In flight simulator projectors the ingress of dust causes a dramatic reduction of the ansi contrast which is crucial to the quality of the large simulation projections. As a result, image details get lost and the realistic immersive experience that is needed for effective flight simulation and training disappears. Moreover dust accumulation on the color wheel will cause color decay, flickering and eventually shut-down.

As for maintenance, because of the specific application of image blending, the adjustment and re-calibration of projectors is even more costly in a flight simulation environment than elsewhere. Needless to say that a dust-sealed projector system with a longer lifecycle and less maintenance will produce significant cost savings.

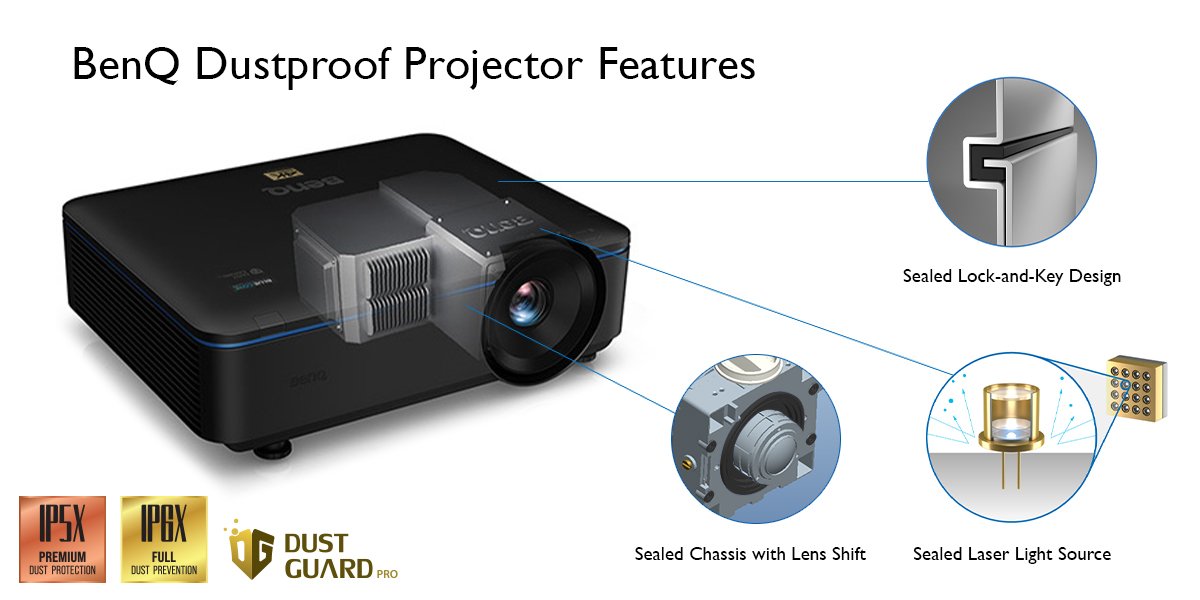

BenQ’s Dust GuardTM technology utilizes sealed optical engine design, colour wheel sensors, and an exclusive vacuum mechanism to block out dust particles. Lens module, colour wheel module and cable outlet are filled with sponge and rubber to prevent dust intervention. Dust GuardTM ensures a significantly prolonged projection lifetime without any colour decay.

With sealed optical engine design, BenQ’s projectors are free from dust intervention, ensures outstanding performance and reliability

To ensure that BenQ’s projectors meet and exceed even the most rigid dust-proof standards, they are submitted to the most gruelling of tests, running hours on end in a dust chamber full of talc powder.

To receive IP5X and IP6Xqualification. IP5X means that dust doesn't enter to interfere with the satisfactory operation of the equipment. IPX6 means that there is no ingress of dust whatsoever. For this qualification the presence of any dust in the enclosure after the test is considered unacceptable. In both cases not a single dust particle is allowed inside the optical engine.

Although these tests seem demanding they are actually not that far from reality. Conditions such as industrial pollution, poor air quality and dusty environments multiply maintenance costs and decimate the life expectancy of a projector. In some locations the Air Quality Index (AQI) reaches peaks bordering 200. The denominating factor for that air quality is destructive fine dust.

This means that every single projector in those countries is uninterruptedly exposed to the massively destructive power of dust.

BenQ’s Dust GuardTM Series guarantees a lasting ultra-high quality image, uninterrupted flight simulation and training in a fully effective subversive experience, even in challenging, dusty environments.

On top of that Dust Guard and its vacuum sealed engine technology significantly extend projector lifetime. Experts agree that IP5X and IP6X rating prolong the life of the investment in projector technology and can shave off substantial maintenance cost - up to 30% compared to conventional lamp projectors.