Projector

Monitor

Lighting

Interactive Display | Signage

Remote Work & Learning

BenQ Europe respect your data privacy. We use cookies and similar technologies to ensure you get the best experience when visiting our website. You can either accept these cookies by clicking “Accept Cookies”, or click “Only Required Cookies” to refuse all non-essential technologies. You can customise your cookie settings here at any time. For further information, please visit our Cookie Policy and our Privacy Policy.

Some essential features on BenQ sites just won’t work without cookies. And having other cookies switched off can seriously affect the way you’ll be able to enjoy our services.

Please check your cookie settings below and turn on any cookies you’re happy with.

“Strictly necessary” cookies can’t be turned off. But Functional and Performance cookies can be turned on or off below. You can learn more about cookies and what they do on our other pages.

If you've chosen to block third-party cookies on your browser, your cookie preferences won't carry over from benq.eu to benq.xx and vice versa. Please make sure to set your cookie preferences in both places.

On

These cookies are essential so that you can move around the website and use its features. Without these cookies services you have asked for cannot be provided.

On

Off

These cookies allow the website to remember choices you make to give you better functionality and personal features.

On

Off

These cookies help to improve the performance of BenQ. If you want to opt-out of advertising cookies, you have to turn-off performance cookies.

BenQ Europe respect your data privacy. We use cookies and similar technologies to ensure you get the best experience when visiting our website. You can either accept these cookies by clicking “Accept Cookies”, or click “Only Required Cookies” to refuse all non-essential technologies. You can customise your cookie settings here at any time. For further information, please visit our Cookie Policy and our Privacy Policy.

Step into the festive season with amazing End of Year Deals at BenQ Store!

Check out all our End of Year Deals hereProjector

Monitor

Lighting

Interactive Display | Signage

Remote Work & Learning

Projector

Monitor

Lighting

Interactive Display | Signage

Remote Work & Learning

Wireless PresentationStore

Color Consistency Technology is a unique proprietary technology developed by BenQ to enhance the factory calibration performance. The benefit of incorporating the color consistency technology is to ensure the colors on all units of the same BenQ Professional monitor model will look very similar, no matter what panel is used, and which production line is utilized. However, before we go into the technical details about the technology, we need to establish the importance of factory calibration of color.

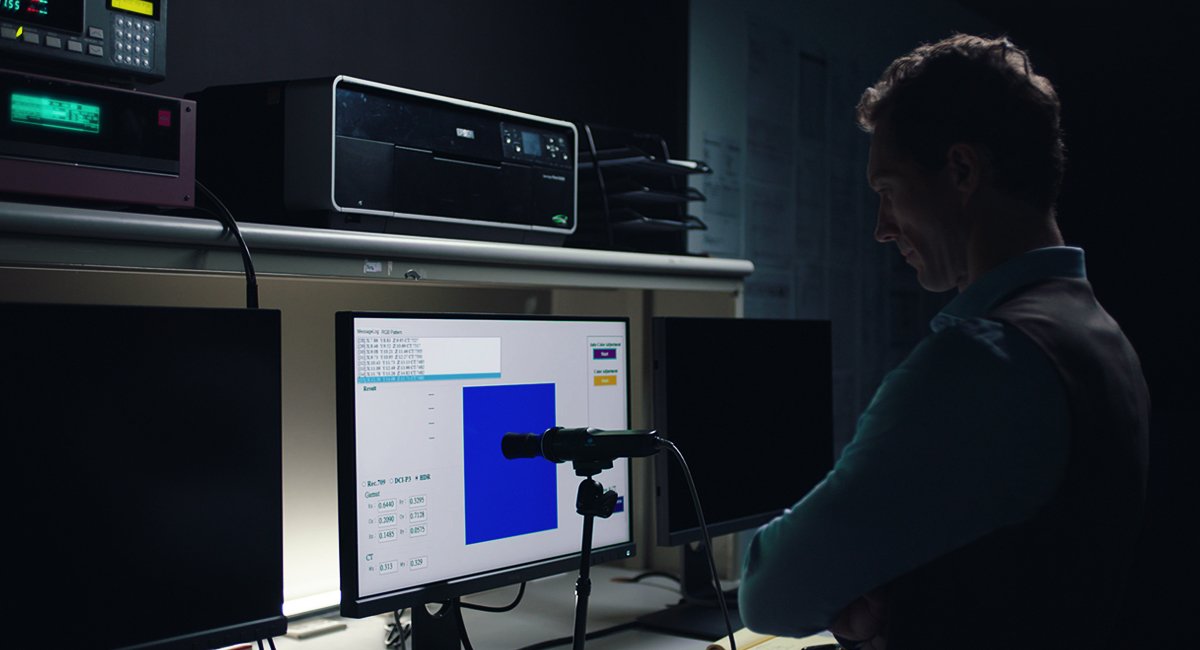

The reason why every unit of BenQ professional monitors went through a rigorous color calibration process at the factory before it shipped out is because our aim is to provide our users with the best out-of-box user experience. This includes worry-free color accurate color modes to use from Day 1. Hence, the calibration must be done at the factory with accurate measurement, as shown in Figure 1.

Figure 1: Accurate Factory Measurement

But we have had encountered some very surprising phenomenon after the color calibration process was completed on the BenQ professional monitors We put different monitors side-by-side to compare, and none of them looked the same, as illustrated in Figure 2. It was a very disturbing news since all the monitors were calibrated to the same color xy-coordinates, and the expectation was the colors should be more or less the same, or at least ‘similar’ to each other. But in reality, it was not the case at all. It was necessary to develop a ‘conversion’ system so that the measurement result has to correlate to the visual result. Hence, this is the starting point of developing color consistency technology.

Figure 2: Same Color Coordinates Reported but with Very Different Visual Result

When we investigated the phenomenon further, we found there are two major factors which cause the discrepancies between the measurement and the visual expectation. One is the panel vendor and, and another one is the measurement device. We will describe in more detail in the following paragraphs about these two factors.

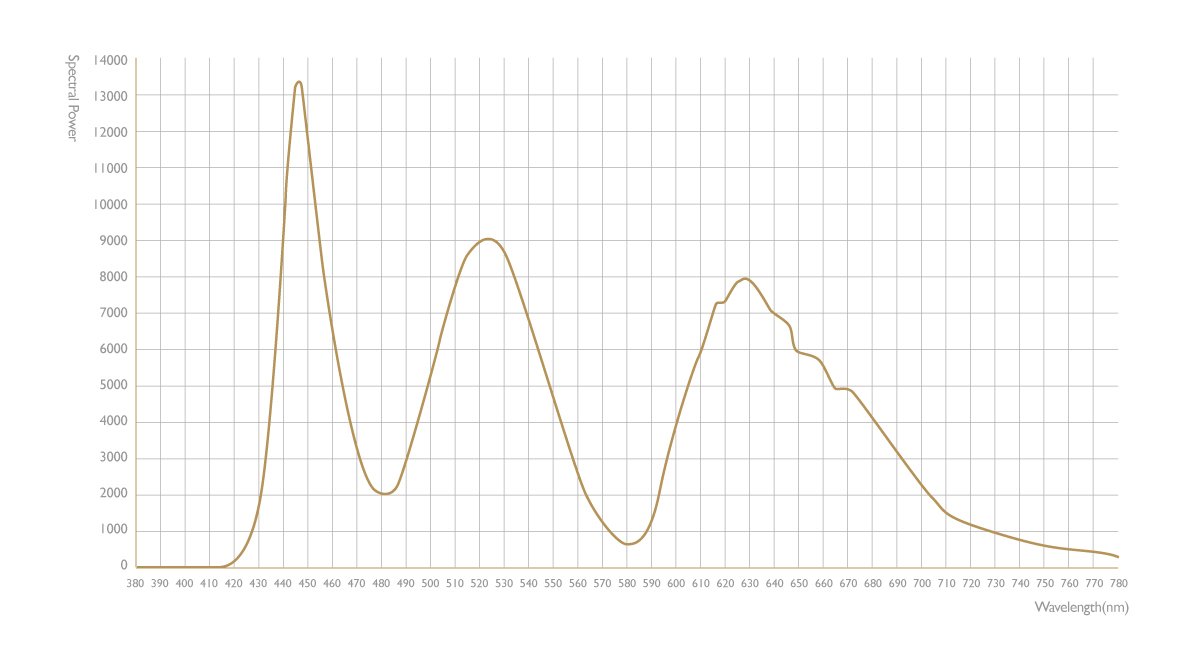

In order to eliminate the effect of the measurement device to the phenomenon, we utilized a spectroradiometer to calibrate the panels from different panel vendors. A spectroradiometer is a measurement device which measures the spectral power distribution of a light source, in this case, the light emitted from the panel, and gives the color values. It is commonly agreed that the color values given from a spectroradiometer is more accurate than other type of devices due to the measurement mechanism and precision. The measurement device often used in the factory is categorized as XYZ-based filter colorimeter. However, due to the precision required, the measuring time is long compared to the XYZ-based filter colorimeter. So, it would not be feasible to utilize to deploy spectroradiometers in a production line. Out of expectation, when the panels are calibrated to the same color values by the spectroradiometer, we found a high agreement in terms of visual expectation across different panels.

This leads us to wonder why we could achieve color consistency using spectroradiometer but not using colorimeter. The only viable explanation is that spectroradiometer provides more color information than colorimeter does. For example, spectroradiometer is capable of measuring 380 nm to 780 nm with 1 nm interval; that is equal to 401 measurement. And colorimeter can only give 3 measurement. Therefore, a lot of information could be lost if colorimeter is utilized.

Figure 3: Measurement Made by Spectroradiometer; from 380 nm to 780 nm with 1 nm interval.

In the factory, there might be more than one production line, hence, more than one measurement devices will be used in the factory calibration process to manufacture BenQ PhotoVue Photographer monitors and DesignVue designer monitors. As we have learned that different measurement devices may deliver different measurement and visual results, as shown in Figure 4. And it is not always feasible to specify the exact unit of measurement device to be utilized during the manufacturing process. Furthermore, the measurement devices will also decay with time. Therefore, it is crucial to establish a method to ‘calibrate’ the measurement devices so all of the devices would agree on each type of panel to avoid different visual calibration result from different measurement devices. So, once the ‘calibration method’ of the measurement devices is in place, we could ensure that all measurement devices could deliver the same color values, hence, deliver the same visual calibration result across different production lines, as illustrated in Figure 5. This would improve efficiency dramatically without sacrificing performance.

Figure 4: Monitors Manufactured from Different Production Lines without Color Consistency Technology

Figure 5: Monitors Manufactured from Different Production Lines with Color Consistency Technology

BenQ’s Color Consistency Technology allows us to further enhance the factory calibration process and enable us to deliver similar calibration result regardless the panel type and production line utilized. Therefore, when you purchased two or more units of the same BenQ Professional monitor model, the monitors will look very similar visually when you first turn on the monitors. So, you could spend more time on retouching your photos, but not frustrating with your monitors why they don’t look the same.

Thanks for your feedback!

Subscribe to Our Newsletter

Stay tuned for our product launches, upcoming news and exclusive benefits.

Subscribe